Navigating Printer Technology: Unfolding the Ciss Systems

Introduction

In the ever-evolving realm of printer technology, CISS systems have emerged as a game-changer for their cost-effectiveness and efficiency. The constant need for ink refills is largely eliminated, and the uninterrupted printing process adds a new level of convenience. This article aims to shed light on what CISS systems are, their functioning, their benefits, ways to implement them, common issues, and their solutions along with a few FAQ's to round off your understanding.

What is a CISS System?

Delving into the world of printing technologies, the Continuous Ink Supply System (CISS), popularly known as a bulk ink system, promises several advantages. It represents a substantial evolution in the field, providing an unbroken supply of ink to the printer, thus eliminating frequent replenishment of cartridges.

Key Elements of a CISS System:

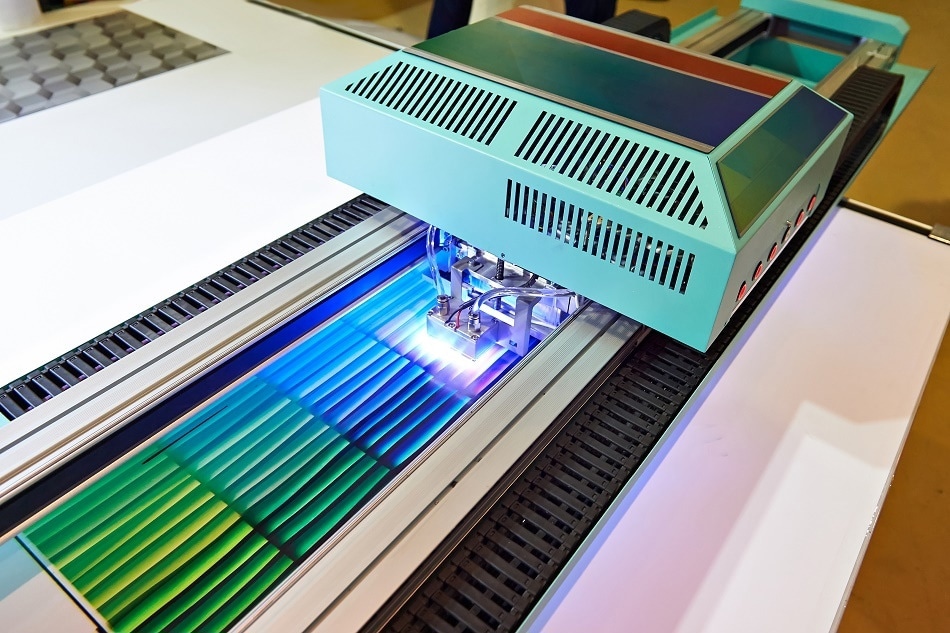

- Reservoirs: These act as stations for storing ink, termed as ink tanks, designed to maintain ample ink supply for long periods.

- Tubes: These serve as passageways, connecting the reservoirs with the printer's ink cartridges. The tubes facilitate the easy transfer of ink from the reservoir to the cartridges.

- Cartridges: Installed inside the printers, these are key components that receive ink from the reservoirs via tubes to accomplish print jobs seamlessly.

The primary function of CISS is to ensure that the printer has a smooth and consistent supply of ink. So, that irritating pause in the middle of printing to replace cartridges becomes a thing of the past. In essence, the CISS works towards making your printer reliant with its sustainable and robust approach, driving efficiency in the printing process. In the next section, we'll explore the workings of the CISS System.

How Does a CISS System Function?

Appreciating the workings of a CISS system requires unraveling the mechanism of its moving parts. The interaction between the storage reservoirs, coupled with narrow conduits and ink cartridges, results in the seamless functioning of this revolutionary technology. Let's break it down:

1. Storage Reservoirs: These are small, reusable, and refillable containers where the ink resides. They hold a significantly larger quantity of ink than traditional cartridges, thereby facilitating longer periods of uninterrupted printing.

2. Tubes: Serving as the transmission lines, these narrow tubes form the physical link between the storage reservoirs and ink cartridges. The consistent pressure ensures a steady flow of ink via these tubes.

3. Ink Cartridges: Unlike regular cartridges that need to be replaced when the ink runs out, CISS system cartridges are simply filled from the connected tubes. Through this replenishment process, the printer always has a sufficient and seamless supply of ink despite continuous printing.

In essence, the CISS system operates on an 'on-demand basis' - automatically sourcing ink from the reservoirs when the printer is in operation. This mechanism ensures quality prints, excellent efficiency, and substantial cost savings, making the CISS system a compelling choice in printer technology.

Why is a CISS System Beneficial for Printers?

The popularity of the Continuous Ink Supply System (CISS) lies in the primary benefits it brings to the table. Here's a bullet-point breakdown showcasing why the CISS method is advantageous for printers:

- Monetary Advantage: The initial installation cost of a CISS system might seem high, but it is an investment that yields returns in the long run. When compared to the recurring cost of cartridge replacements, CISS proves more economical. This can reflect a significant decrease in printing expenses over time.

- Boosts Productivity: Say goodbye to the hassles related to frequent cartridge changes. CISS allows uninterrupted printing which saves time, hence enhancing productivity. This is bolstered by the fact that the CISS system can print hundreds, if not thousands, of pages before needing a refill.

- Maintained Print Quality: One of the biggest upsides of a CISS system is the consistently high print quality. The continuous flow of ink ensures each print is as clear as the one before, contributing to higher quality results in every print job.

- Eco-Friendliness: Making a significant contribution to environmental sustainability, CISS systems reduce waste production. Traditional printer cartridges contribute in large amounts to plastic waste, but with CISS the only waste is the ink, resulting in less overall environmental impact.

The CISS proves its worth through its simplicity, cost-effectiveness and high output, making it an excellent choice for businesses looking to enhance their printing processes as well as those inclined towards eco-friendly options.

How to Implement a CISS System in Your Printer?

Installing a CISS system in your printer may seem daunting at first glance, but with these simple steps, you will find the process relatively straightforward. Below is a detailed guide outlining each necessary step to ensure a smooth installation process.

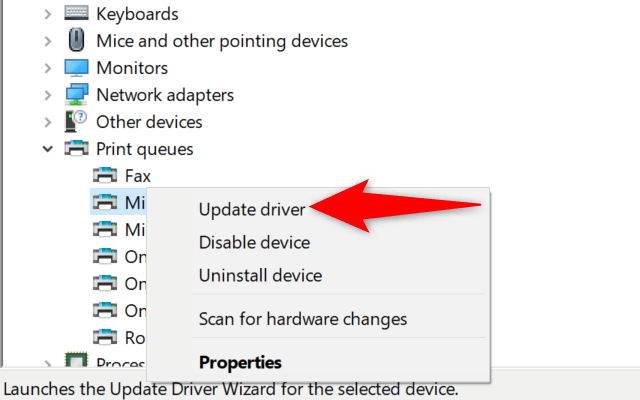

1. Identify a Compatible CISS Kit: The first step involves purchasing a CISS kit that is specifically designed for your printer model. It's important to remember that not all CISS kits are universal, and compatibility is key to ensuring a successful installation.

2. Position the CISS Tanks: Once you've procured the CISS kit, position the ink tanks next to your printer. It’s crucial to place the tanks on the same level as the printer because any height difference can disrupt the ink flow.

3. Install the Ink Cartridges: This step involves inserting the ink cartridges included in your CISS kit into the printer head. Make sure to follow the manufacturer's instructions for this step as incorrect installation can result in print quality issues or damage to the printer.

4. Connect the Tubes: With your cartridges installed, it's time to connect the ink cartridges and the CISS ink tanks using the provided tubing system. This is what facilitates the continuous ink flow from the tanks to your printer.

5. Test the Ink Flow: After your system is set up, it's important to test the ink flow. This can be done by running a few test prints to ensure the ink is flowing correctly and that the print quality is up to standard.

6. Adjust the Lid and Initialize the Printer: The final step involves adjusting the printer's lid to accommodate the ink tubes and then initializing the printer according to the manufacturer’s instructions.

Remember, the process of installing a CISS system requires patience and precision, but the reward lies in the cost savings, productivity boosts, and the high-quality prints your printer will be able to produce. Always follow the manufacturer's guidelines and if any issues arise, reach out to professionals for assistance.

Overcoming Potential Hurdles: Common CISS System Problems and Solutions

No technology is immune from glitches, and CISS systems are no exception. However, understanding these potential hitches and their solutions can help ensure smoother and more efficient operation. Below are two of the most common challenges faced along with their respective rectification measures.

Air Bubbles in the Ink Tubes

This problem can often cause the incorrect amount of ink to get dispensed to the cartridges or even completely disrupt the ink flow.

Solution: Regular maintenance plays a key role here. First, check that the tanks are not positioned too high or too low as improper positioning can generate air bubbles. If bubbles are present, you might need to bleed the system. This involves disconnecting the cartridge end of the tubes and allowing the ink to flow freely for a brief period, which should push the air bubbles out.

Inadequate Ink Flow

This issue occurs when ink does not flow smoothly from the tanks to the cartridges, causing inconsistent print quality.

Solution: Again, take note of the position of your ink tanks. Positioning them at a level too high or low compared to the printer can induce improper ink flow. If this doesn't rectify the issue, try cleaning the tubes and cartridge nozzles as grime and debris can cause blockages.

In conclusion, keeping your CISS system well-maintained by timely and regular check-ups greatly increases the lifespan and efficiency of your printer. Always consult with the manufacturer or a professional in case of unresolved issues or doubts.

Conclusion

CISS has revolutionized printer technology with its continuous ink supply ensuring cost-effectiveness and high productivity. While setup and maintenance might require some effort, the long-term benefits outweigh these concerns.

Related FAQs about what is a ciss system for printers

What are the components of a CISS System?

A CISS system comprises three primary components. The first is multiple reservoirs or tanks that store ink. These tanks are connected to the printer's cartridges using narrow tubes, which represent the second component. The ink cartridges that receive the ink from the tanks constitute the third component of the system.

Does a CISS System save money in the long run?

Yes, a CISS System does save money in the long run. Although the initial setup may seem costly, it eliminates the frequent need to replace cartridges. As the ink can be purchased in bulk which is considerably cheaper, you observe significant cost savings over time.

Is a CISS System eco-friendly, and how does it reduce waste?

Indeed, a CISS System is eco-friendly. Traditional ink cartridges generate significant plastic waste when replaced, but with a CISS system, this is majorly reduced as the ink tanks are refillable and the cartridges are reusable, thereby significantly cutting down on waste.