The Creative World of 3D Printing: Discover What People Make With 3D Printers

Introduction

3D printing, once a fantasy of sci-fi literature, is now a reality in the global market. Its impact spans across households and industries, pushing boundaries and offering a new way to transform digital data into tangible, physical items. This article delves into the innovative world of 3D printing, exploring what people can make with such technology—from household items to medical equipment and gourmet meals. It will also glimpse into the future to forecast the possible game-changing innovations 3D printing might bring.

How Does 3D Printing Work?

To truly comprehend the capacity of 3D printing, it's essential first to unfold the operational mechanics behind it. Here's the fascinating process of 3D printing, demystified:

1. Designing the Concept: Everything commences with an idea - a 3D design. Crafted using computer-aided design (CAD) software, the blueprint encapsulates the desired object's specifications and structural detail.

2. Slicing the Model: This digital model is then methodically divided into extremely thin horizontal layers (slices). Often, slicing programs are used for this purpose. Each slice will act as a blueprint for the printing process.

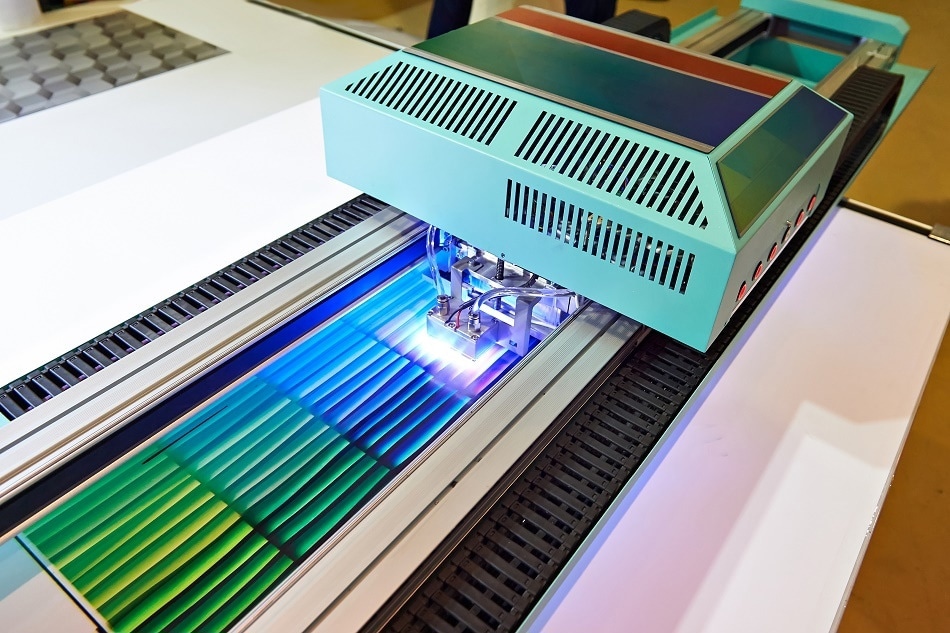

3. Preparation of the 3D Printer: The 3D printer gets prepped based on the type of printing technology being used. This stage often involves loading the required materials, such as plastic or resin, into the printer.

4. The Printing Process: Using the slice blueprints, the 3D printer builds the object layer by layer. It meticulously follows the design, adding material where necessary. Some printers use a heating process to melt the material, which solidifies into the desired shape.

5. Object Formation: As the printer adds more layers, the object starts taking shape, gradually transforming the digital design into a tangible object.

6. Layer Cooling and Final Touch: Once the final layer is added, the object is given time to cool and harden. Depending on the complexity of the design, this process can take a few hours to several days.

In essence, the device converts a series of digital cross-sections into physical layers, thus realizing the object that existed only in the digital realm into our concrete world. It's a versatile and intricate process, blending creativity with technology to produce stunning results.

What Common Items Do People Create with 3D Printers at Home?

The convenience and affordability of personal 3D printers have positioned them as a popular choice for home use. Their versatility enables users to design and fabricate a wide spectrum of items right from the comforts of their homes, bringing about a new era in domestic manufacturing. Here, we delve into the kind of everyday items homeowners typically create using a 3D printer:

1. Replacement Parts: Broken a small part of an appliance? Instead of purchasing a new unit or waiting for a spare part to arrive, homeowners use 3D printers to develop customised replacement parts.

2. Kitchenware and Utensils: The flexibility of 3D printing allows for the creation of customised kitchen tools and utensils tailored to specific needs and tastes.

3. Planters and Gardening Tools: Green enthusiasts frequently design and print unique planters or other gardening accessories, adding a personal touch to their home gardens.

4. Fashion Accessories: From bracelets to eyeglass frames, the scope for crafting unique fashion accessories with 3D printers is phenomenal.

5. Models and Figurines: 3D printers have been a boon for hobbyists and collectors who can now create intricate models and figures at home, ranging from architectural models to characters for board games.

6. Educational Tools: 3D printers can produce anatomical models, mathematical shapes, and a vast array of other educational tools that can facilitate interactive learning for children at home.

A Statista survey report reveals that approximately 37% of 3D printing is used for prototyping, showing the extensive influence of this technology in homes. It also underscores the shift towards locally-produced, on-demand goods, driving sustainable and self-sufficient living. As technology continues to improve and become more accessible, we can anticipate an even more diverse range of uses for 3D printers in the home.

How are 3D Printers Changing the Face of Medicine and Healthcare?

The healthcare industry is experiencing revolutionary evolutions due to the advent of 3D printing technology. From improved surgical planning to personalized patient care, 3D printing plays a pivotal role. Below, we discuss the major ways this technology is changing the face of medicine and healthcare:

- Enhanced Surgical Precision: 3D printers can create patient-specific models based on MRI or CT scan data. These models are used by surgeons to plan operations, leading to increased procedural efficiency, reduced surgical risks, and improved patient outcomes.

- Personalized Prosthetics and Implants: Traditional prosthetics often suffer from fitting issues. However, by using 3D printing techniques, prosthetics and implants can be customized precisely, ensuring a better fit and heightened comfort for the patients.

- Potential in Bioprinting: Perhaps one of the most exhilarating applications of 3D printing lies in bioprinting - the process of creating cell patterns in a confined space using 3D printing technologies, where cell function and viability are preserved. Using this technology, scientists hope to build layered tissues and organs, which could be a game-changer in the organ transplant field.

To quantify these advancements:

- A study conducted by the New York University School of Medicine found that using 3D models in kidney transplant cases reduced surgery time by 35 minutes - potentially saving up to $2700 in surgical costs.

- According to the Journal of Clinical Orthopaedics and Trauma, 3D-printed prosthetics costs are significantly lower than traditional prosthetics, thus making them more accessible to patients in need.

These innovative applications of 3D printing are merely the tip of the iceberg. The technology continues to unfold its full potential, paving the way for advancements that we can only begin to imagine.

How is 3D Printing Pushing Boundaries in the Fashion Industry and Food Industry?

3D printing is significantly altering the dynamics of both the food and fashion sectors, driving technological innovation while fostering an atmosphere of creativity. Let's delve deeper into its transformative impact on these industries:

1. Fashion Industry:

- Experimentation: 3D printing empowers designers to push the boundaries of their creativity, producing unconventional, intricate, and avant-garde wearable pieces.

- Customization: This technology opens portals to personalizing designs, ensuring each product uniquely fits the client's aesthetics.

- On-demand Manufacturing: It accelerates the production process, which can fulfill orders promptly and eliminate excessive inventory, thereby minimizing waste.

Popular brands like Adidas and Chanel have already launched products using 3D printing technology. According to Statista, the worldwide market for 3D printed clothes, jewelries, and shoes is expected to reach $5.3 billion by 2030.

2. Food Industry:

- Culinary Artistry: Chefs and food artists are using 3D printers to sculpt complex patterns and shapes, transforming food into intricate works of art.

- Customized Food Items: 3D printing can potentially be applied to create personalized meals based on individual dietary requirements, reducing food waste and promoting healthier eating habits.

A survey conducted by Natural Machines found that almost 35% of people would like to own a 3D food printer at home, indicating its acceptance in society.

3D printing, with its flexibility and precision, is truly revolutionizing the conventional boundaries in both the fashion and food industries. As advancements continue, the potential benefits and possibilities seem boundless.

What Potential Future Innovations can be Expected from 3D Printing?

H2: Anticipating the Future: Innovative Contributions Expected from 3D Printing

The future of 3D printing seems limitless, as it is set to revolutionize and disrupt traditional industries in ways we might not yet fully envisage. Below we explore some fields where serious game-changing innovations are anticipated:

1. Construction Industry: 3D printing is tipped to radically change the way we build. It holds the promise of rapid construction, creating sustainable and affordable housing more quickly than traditional building methods. Imagine printing an entire house within 24 hours!

2. Space Exploration: NASA plans to harness 3D printing technology for building habitats on other planets, pushing the final frontier's boundary. This monumental shift will not only reduce costs and risks but also solve the challenge of transporting materials through space.

3. Consumer Market: The common household could witness one of the most significant transformations. In a not-so-distant future, 3D printers might be as ubiquitous as our current printers, with the potential to print anything a household requires, on demand.

4. Education: The classroom of the future could see every student using a 3D printer, encouraging creativity, critical thinking, and problem-solving skills.

5. Environmental Impact: An intriguing anticipated innovation is the use of recycled plastics as printing material, making 3D printing an eco-friendly process.

As we embrace these futuristic possibilities, the question evolves from 'What do people make with 3D printers?' to 'What can't people make with 3D printers?' It's an exciting testament to the potential of this transformative technology.

Conclusion

3D printing is halfway through its metamorphosis from novelty to necessity. It's shaping our world, offering a new level of customization and personalization, democratizing manufacturing, and revolutionizing various industries including healthcare, fashion, food, and beyond. As technology continues to evolve and become more accessible, the question will soon shift from 'What do people make with 3D printers?' to 'What can't people make with 3D printers?'

Related FAQs about what do people make with 3d printers

How environmental-friendly is 3D printing?

3D printing has the potential to be environmentally friendly. It minimizes waste as it involves additive manufacturing (building objects layer by layer) rather than traditional subtractive manufacturing methods. Also, there's ongoing research into using recycled plastics, biodegradable materials, and non-toxic alternatives as printing materials. Yet, like any technology, its environmental impact heavily depends on how we opt to use it.

What new industries could be impacted by 3D printing in the future?

While 3D printing's impact is already felt across numerous industries, its future implications might stretch further. We could see considerable influences in areas like aerospace, architecture, pharmaceuticals, and more. It might even create entirely new industries, such as bioprinting organisms or on-demand manufacturing services, altering the way we comprehend production and design.

How accessible and affordable are 3D printers for everyday home use?

3D printers have become significantly more accessible and affordable over recent years. Simple models suitable for home use can be purchased for a few hundred dollars. However, more advanced and professional-grade models can cost several thousand. As the technology continues to evolve, it is expected that 3D printers will become even more budget-friendly and widely accessible.