Unleashing the Potential of 3D Printing: What Can You Make?

Introduction

What Is 3D Printing and How Does It Work?

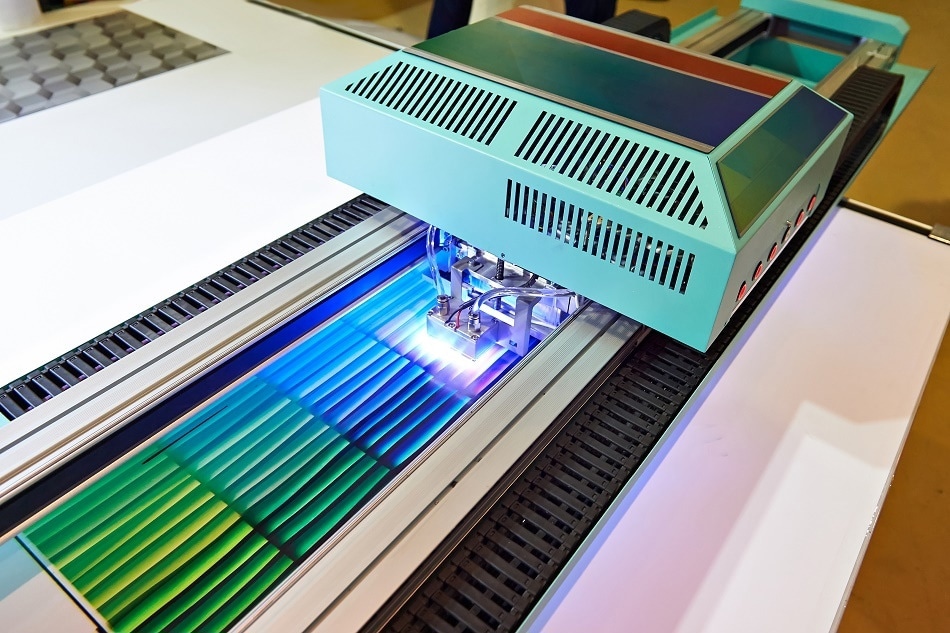

3D printing, also known as additive manufacturing, is a groundbreaking technology that has opened up infinite possibilities when it comes to creating tangible objects. But what is 3D printing, and how does it function? Here's a brief rundown:

- Definition: 3D printing is a process that transforms a digital design into a real, three-dimensional object.

- Functioning: It operates by depositing multiple layers of material, one on top of the other, until a physical object is formed.

- Computer-Aided Design (CAD): This is the primary software used to craft the 3D model for printing.

- Slicing: The digital model is then partitioned into numerous horizontal layers by 3D printing software.

- Layer Deposition: The 3D printer interprets these digital layers and carefully places the raw material layers to develop the object gradually.

From simple crafting tools to complex industrial components, this innovative technology transcends limitations, empowering us to bring any idea to life.

What Can You Create with a 3D Printer in Your Everyday Life?

Crafting Household Items with 3D Printing

The world of 3D printing offers endless opportunities for creative potential right in your own home. Have you ever considered crafting your own household items? It's not only convenient but also a fun project. With 3D printing, you can create practical items such as:

- Custom kitchenware: Think tailored utensils, creative cookie cutters or unique serving dishes.

- Replacement parts: No need to worry about misplaced or broken components of your appliances.

- Home decor: From customized picture frames to intricate lampshades or shelf brackets, your imagination is the limit.

DIY Jewelry and Fashion Accessories using 3D Printing

If you fancy personal style and are drawn to unique fashion statements, 3D printing is your perfect partner. It allows room for creativity and uniqueness while also providing an opportunity to wear self-designed pieces which are not just special but potentially lower-cost. Here are some items you can create:

- Personalized jewelry: From geometrically precise earrings to complex necklace designs, jewelry crafting has never been so accessible.

- Innovative fashion accessories: Belts, sunglasses, watches - you name it.

- Footwear: Believe it or not, 3D-printed shoes are becoming a popular trend, merging comfort with customization.

From creating tasteful home ambiance to curating your style statement, 3D printing provides you with adventurous ways to use technology in everyday life.

How Does 3D Printing Influence Industries?

3D printing is transforming the way a multitude of industries operate, bringing along radical shifts in manufacturing processes, customization, prototyping, and so much more. Within these changes, two fields stand out – the medical sector and manufacturing industry.

The Medical Sector: Where 3D Printing Saves Lives

The medical field is experiencing profound changes due to the implementation of 3D printing. Here are ways this technology is reshaping the medical sector:

- Custom-made prosthesis: 3D printing allows the fabrication of custom made prosthetics and orthotics, dramatically enhancing their comfort and functionality.

- Medical models for surgery preparation: Surgeons are now using 3D printed models of patients’ body parts to plan surgeries, enhancing surgical outcomes and decreasing operation times.

- Bioprinting: A cutting-edge application of 3D printing is the creation of artificial tissues and organs, also known as bioprinting. While still in early stages, it holds the promise of addressing organ transplant shortages in the future.

Manufacturing Industry: The Future is Being 3D Printed

The manufacturing sector has been revolutionized thanks to 3D printing in the following ways:

- Rapid prototyping: 3D printing offers the possibility of creating precise prototypes quickly and inexpensively, accelerating the product development process significantly.

- Production of complex designs: Traditional manufacturing methods can struggle with complex geometries. In contrast, 3D printing can easily handle intricate designs, expanding the range of products possible.

- Lowering costs and waste: 3D printers build objects layer by layer, using exactly the amount of material needed. This not only reduces production costs but also minimizes waste, aligning with sustainable manufacturing practices.

3D printing technology is thus proving to be a transformative force across various industries, redefining how things are made and services are provided.

What Are Some Innovative Ways to Use 3D Printing for Prototyping and Education?

3D Printing has opened the gates to innovation, particularly in the fields of prototyping and education.

Enhancing Prototyping Efficiency with 3D Printing

3D printing brings several efficiencies to the prototyping process, making it an attractive option for designers and engineers.

1. Speed: 3D printing accelerates the prototyping process, turning designs into physical models within hours, compared to traditional methods that might take days or weeks.

2. Cost-Effective: It eliminates the need for expensive molding tools.

3. Flexibility: 3D printing allows quick and easy iterations of design modifications, making it simpler to test and improve prototypes.

4. Precision: The ability of 3D printers to reproduce every minor detail results in high-quality prototypes.

However, it’s worth noting that while 3D printing provides numerous advantages, there will be scenarios where traditional prototyping methods may be more appropriate. Factors such as materials, load-bearing needs, and budget could play a role in this decision.

Implementing 3D Printing in The Education Sector

Educational institutions worldwide are increasingly incorporating 3D printing into their curriculum, unlocking multiple benefits.

1. Tangible Learning: 3D prints offer tactile representation of theoretical concepts, fostering better understanding and retention.

2. Creativity and Innovation: It encourages students to think out-of-the-box and be creative.

3. Skills Development: Learning 3D printing cultivates technical skills and problem-solving abilities, essential for future tech-driven workplace.

Yet, there are challenges in fully integrating 3D printing into education. The need for training teachers, high initial costs, and safety are key concerns that must be properly addressed.

In both prototyping and education, 3D printing presents a paradigm shift, offering a plethora of opportunities to explore and innovate.

Conclusion

Absolutely. You can design personalized jewelry or fashion accessories with intricate patterns that would be impossible to craft by hand. 3D printing provides limitless creative freedom, enabling you to craft original pieces, right from earrings, bracelets, pendants, to belts.

Frequently Asked Questions

Though 3D printing is becoming popular for personal use, it's in industries where this technology truly shines, revolutionizing how we manufacture, prototype, and innovate.

Related FAQs about what do you make with 3d printers

Are 3D Printers Accessible to the General Public?

Yes, 3D printers are accessible to the general public and are increasingly becoming a common fixture in homes, schools, and libraries. They come in various sizes and price points, making it feasible for individuals to own them for personal and educational use.

What Materials Can Be Used in a 3D Printer?

3D printers can use a wide variety of materials, ranging from thermoplastics like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), to resins, metals, ceramics, and even food material. The choice of material depends on the printer type and the intended use of the printed object.

What Are the Limitations and Challenges of 3D Printing?

Although 3D printing is innovative, it comes with limitations and challenges. These include the high costs of industrial-scale printers, time-consuming printing process for larger or more detailed objects, limitations in the types of materials that can be used, and quality control issues.