Unveiling the Capabilities: What Can Inkjet Printers Really Print On?

Introduction

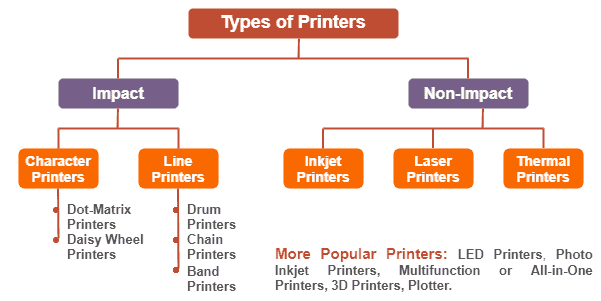

Inkjet printers, known for their versatility, are remarkably capable of printing on a range of different materials. Far beyond the realms of just papers and photographs, their utilization has seen a foray into textiles, plastics, ceramics, vinyl, and even wood. As technology continues to evolve, so do inkjet printing possibilities, fostering curiosity about these printers' limits. This article explores what inkjet printers can print on, offering an understanding of its conventional and unconventional use-cases.

What Are the Basic Media Options for Inkjet Printers?

Inkjet printers, lauded for their versatility, can accommodate diverse printing media, extending beyond just regular printing paper. Here’s a rundown of the common materials that inkjet printers are compatible with:

1. Various Paper Types: Standard office inkjet printers are designed to handle a multitude of paper sizes and types. This includes your everyday A4 sheets, legal papers, and even miniature note sizes.

2. Envelopes and Labels: Need to print addresses onto envelopes or labels? Inkjet printers make it a breeze, offering smooth and clear prints.

3. Transparencies: Inkjet printers are also capable of printing on transparencies, lending well to creating overhead projector presentations or achieving certain art or craft goals.

4. Photo Paper: For the photographers and scrapbookers, high-resolution, professional-grade pictures can be printed directly from your desk using specific photo paper in an inkjet printer.

5. CDs and DVDs: Interestingly, some modern inkjet printers are equipped with the technology to print on CDs or DVDs, offering a unique way to personalize or brand these items.

6. Heat Transfer Papers: Special heat-transfer papers work well with inkjet printers for printing designs and subsequently transferring them to textiles, opening doors to custom t-shirt designs.

7. Inkjet PVC Cards: For businesses, especially, inkjet printers can efficiently print on Inkjet PVC cards, allowing for in-house production of ID cards.

With the advancement in inkjet printing technology, this list is steadily growing and offering more resourceful and innovative applications.

How Can Inkjet Printers Print on Textiles?

In an incredible leap within the textile industry, inkjet printers have significantly carved out a niche in a field not traditionally their own. The process of their integration into the textile domain is through 'Direct to Garment' (DTG) printing. Fascinatingly, inkjet printers manage to leave a lasting impression on the fabric without altering the feel of the garment. How is this achieved? Let's take a detailed view:

- Special Ink Use: The essence of DTG printing lies in specialty water-based inks. These specially formulated inks, when applied to the fabric, integrate seamlessly without hampering the material's tactile quality.

- Printing on Dark fabrics: White Ink Management Systems amplify the inkjet printers' ability by enabling printing on dark fabrics. These technologically advanced systems meticulously maintain the integrity of the designs.

- Fast-Drying Inks: One of the greatest challenges of textile printing – drying time, is cleverly battled with rapidly drying inks. Therefore, hurry need not be a worry in DTG printing.

The textile industry has significantly benefited from inkjet printers, paving the way for highly customizable clothing and accessories. This innovative technology caters not just to the large-scale textile industry, but also small businesses, replacing traditional screen-printing methods.

In essence, the impact of inkjet printers on the textile domain has been nothing short of transformative. With its unique capabilities and promising advancements, the versatility of inkjet printing continues to unfold.

What Makes Plastic and Vinyl Viable Options for Inkjet Printers?

The use of plastic and vinyl in inkjet printing has become increasingly popular due to their resilient properties and broad application range. Here's a more detailed look into the factors contributing to their viability as preferred printing materials.

- Durability: Given their tough nature, plastic and vinyl are exceptionally durable. This makes them ideal materials for outdoor banners, vehicle wraps, labels or any signage that need to withstand the elements.

- Ink Compatibility: Solvent-based inks used by inkjet printers can form a robust bond with plastic and vinyl. This enables the creation of vibrant and weather-resistant prints, ensuring longevity and vibrant colour pay-off.

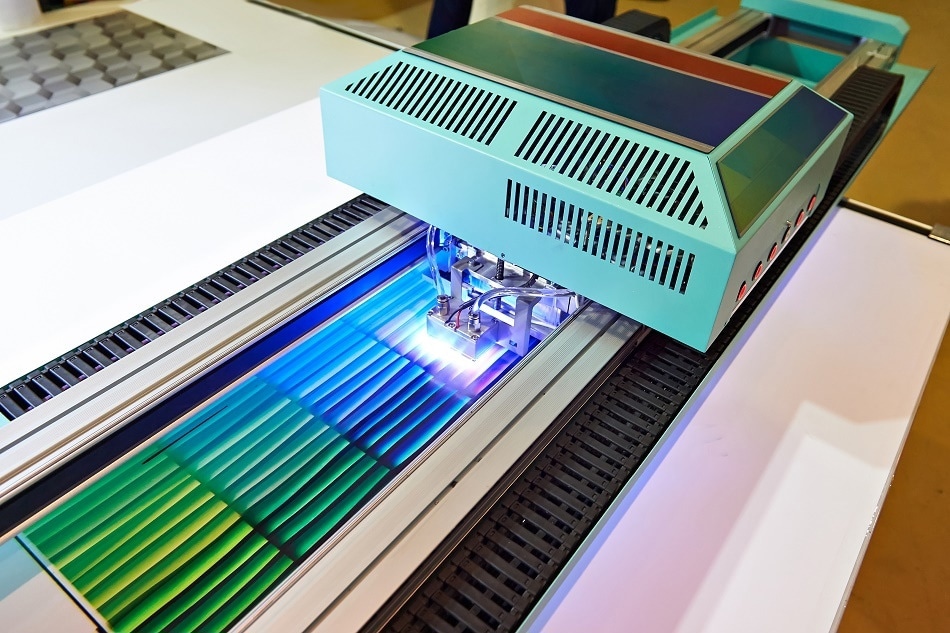

- Innovative Technologies: Breakthroughs in UV-LED inkjet printing allows direct printing on plastic, resulting in immediate curing or drying of the ink. It speeds up the overall process and ensures the colors remain vibrant and dynamic.

- Unique Applications: Vinyl adhesives play a key role in the growing trend for personalization, with applications spanning from laptop and cell phone skins to decorative vinyl stickers.

The expansion of inkjet printing onto materials like plastic and vinyl has opened a world of new possibilities in terms of applications and durability. The compatibility of these materials with existing inkjet printer technology and the resilience of the prints made with these materials ensure that this trend is on an upward trajectory.

How Are Unconventional Materials like Ceramics and Wood Used for Inkjet Printing?

Unconventional materials such as ceramics and wood have significantly expanded the scope of inkjet printing. It has paved the way for creativity while redefining customization. Below we explore how ceramics and wood have ventured into the world of inkjet printing:

1. Ceramics:

- Limitless Creativity: 'Direct to Substrate' inkjet printers have made it possible to print directly on ceramics. This radical technology allows for endless possibilities when it comes to personalizing ceramic objects from tiles to pottery pieces, and more.

- Impeccable Durability: Once the printing on ceramics is completed with an inkjet printer, the ink is fused with the ceramic glaze. The application of a kiln post-printing ensures that the design is seamlessly integrated and guaranteed to last a long time.

2. Wood:

- Direct Printing: Utilizing the prowess of UV-LED inkjet printers, printing directly on wood has become reality. This method doesn’t require any pre-coating or priming of the wood, making the process easier and more efficient.

- Instant Results: The UV light on these inkjet machines immediately cures the ink as soon as it hits the wood surface. This 'instant drying' feature assists in achieving bright, vibrant prints that are resistant to wear and tear.

The exploration of unconventional surfaces such as ceramics and wood in inkjet printing has led to an extraordinary array of possibilities in personalized home décor, artwork, and even furniture finishing. This emergence of creativity truly attests to the adaptability and versatility of inkjet technology.

What Are the Future Possibilities in the Domain of Inkjet Printing?

As inkjet printing technology evolves, an array of fascinating future possibilities surfaces. Let's underline some trajectories that this technology might embark on:

1. 3D Printing: One of the most groundbreaking advancements in printing, 3D printing, employs an inkjet-like process to create three-dimensional objects. The technology utilizes 'additive manufacturing', which involves layering materials like liquid plastic or powder till the product is formed –similar to how inkjet printers deposit droplets of ink on paper. A Wohlers Report projects that the worldwide sale of 3D printing products and services will reach nearly $15.8 billion by 2020.

2. Direct to Shape Printing: With Direct to Shape printing technology, inkjet printers can swath ink onto objects of complex shapes, rather than flat papers. This innovative printing style opens a vast application spectrum – from intriguing advertising strategies to high-quality packaging designs in beer, alcohol and personal care products industry.

3. Bioprinting: One of the most exciting future possibilities within inkjet printing is bioprinting. Here, inkjet printers are adjusted to deposit layers of living cells, creating biological tissue. This technology is already being explored for medical applications such as organ printing and tissue regeneration. Its market is estimated to reach $1.82 billion by 2022, according to a BIS Research report.

In a nutshell, the ever-evolving landscape of inkjet printing extends beyond the known horizons, taking us towards a future with increasingly versatile applications.

Conclusion

Inkjet printers have gone beyond just document and photo printing to become versatile, multidimensional tools. Their advancements have not just enhanced the traditional printing domain but have also found unconventional, innovative applications. The future of inkjet printing technology is undoubtedly promising and instills curiosity about the realms inkjet printers will explore in the future.

Related FAQs about what can inkjet printers print on

Are there any specific materials that inkjet printers cannot print on?

Inkjet printers, despite their versatility, may struggle with very thick or heavily textured materials, as they might not feed through the printer correctly. Moreover, materials not designed for inkjet inks may not absorb the ink properly, leading to uneven, faded or smudged prints.

Can using different materials affect the quality of printing with inkjet printers?

Yes, the choice of material significantly influences print quality in inkjet printers. While some materials absorb ink well, ensuring vibrant and sharp prints, others might result in faded or blurred images. Therefore, it's recommended to use materials compatible with inkjet printing to ensure optimal print quality.

How has the evolution of inkjet printers influenced their printing capabilities?

The evolution of inkjet printers has vastly expanded their printing capabilities. Advanced technologies have enabled inkjet printers to effectively print on diverse materials beyond just paper - including textiles, plastics, ceramics, vinyl, and wood. Furthermore, future innovations promise further versatility in this domain.