Unveiling the World of Dye-sublimation Printers

Introduction

In printing technology, several innovations have graced the scene over the years. One popular printing technique you might have come across is the dye-sublimation printing. This technology has taken over the printing business by storm due to its capacity to produce high-quality images with great clarity and depth. In light of this, this article explores the fascinating world of dye-sublimation printers to help you understand what they are, how they function, where they're commonly used, and what to look at when purchasing them.

What Exactly Is Dye-Sublimation Printing?

Dye-sublimation printing is an innovative method that's revolutionized the printing industry, praised for its ability to create high-quality images with remarkable depth and clarity. Here's what it entails in detail:

- Core Technique: At the core of this technique is the utilization of heat to transfer dye onto various surfaces like fabric, plastics, or paper.

- Unique Process: This method stands out for its unique process where the dye, instead of being incident onto the surface, is infused into the material using a heating mechanism.

- High Resilience: The end prints are incredibly resilient, with a notable resistance to both water and fading. This quality alone makes them an excellent choice for applications that require long-lasting prints.

- Understanding 'Sublimation': The term 'sublimation' is very principal to this printing technique. It refers to a distinct phase transition where the dye transitions directly from a solid state to a gas state, skipping the liquid stage entirely. The significance of this phenomenon lies in the fact that it's this very process that allows the dye to permeate the print material in the first place.

So, at its essence, dye-sublimation printing is all about using heat to instigate a ‘phase transition' in dyes to facilitate their diffusion into different print materials.

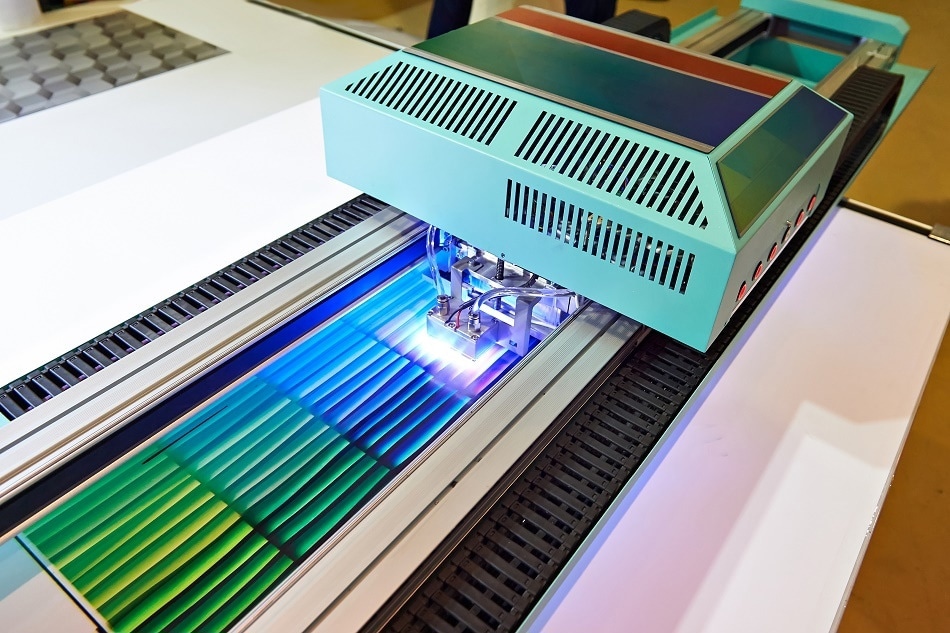

How Does a Dye-Sublimation Printer Work?

Breaking down the functionality of a dye-sublimation printer reveals an enchanting and unique process in the realm of digital print technology. Here are the steps involved in this innovative process:

1. Start with a Special Type of Film: Unlike other printers, dye sublimation uses a unique film loaded with cyan, magenta, yellow and black (also known as CMYK) dyes.

2. Application of Heat: A heating mechanism is employed to activate the dye. This process involves heating the specific areas of the film where the printout will have color.

3. Dye Turns Into Gas: Instead of melting or changing into liquid, the heated dye transforms directly into gas due to the sublimation technique.

4. Infiltration into the Print Medium: The gaseous dye infiltrates the surface of the print medium and is absorbed into it, making for a more enduring and fade-resistant print.

5. Controlled Release of Dyes: The amount of dye released is controlled by the printer's temperature. This enables the blending of different colors for the precise reproduction of images.

6. Solidification Process: The gaseous dye cools down upon entering the print medium and solidifies. The print, at this point, is not just on the surface of the medium but embedded within it. This leads to a vibrant and long-lasting print.

In conclusion, the laws of physics play a significant role in a dye-sublimation printer's operation. With the blend of heat, pressure, and time, this printer magically transitions the dye from a solid state to a gas and back to a solid in the print medium, resulting in incredible printout quality.

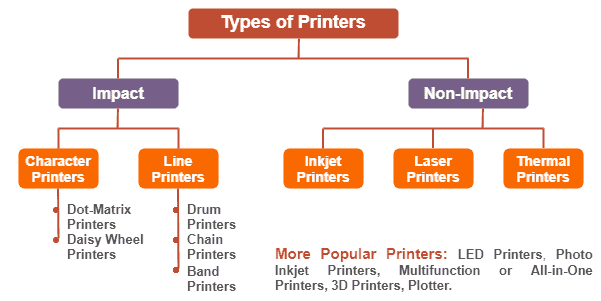

What Sets Dye-Sublimation Printers Apart From Other Printers?

The distinguishing factors that set dye-sublimation printers apart from other types of printers stem from their unique functionalities and output characteristics. Here's a breakdown:

- Direct Infusion of Dye: Unlike conventional printers that merely deposit ink on the material's surface, dye-sublimation printers infuse the dye directly into the printing material. This unique attribute eventually results in prints that are not just eye-catching but also resistant to fading.

- Bold, Vibrant Prints: Dye-sublimation printers are celebrated for producing impressively vibrant and highly detailed prints. The end product is more realistic and rich in detail, enhancing the overall aesthetic appeal.

- Smooth Color Gradients: Compared to other printers, dye-sublimation printers excel in creating smooth gradation of colors. They can transition between different shades seamlessly, providing prints with incredible depth and dimension.

- Permanence and Durability: The prints produced by dye-sublimation printers are notably resilient, lasting for a long period without fading or smearing.

However, a potential downside to consider:

- Higher Consumable Costs: These printers necessitate the use of specialized dye-sublimation inks and thermal dye print media. The cost of these consumables can be a little higher compared to standard inkjet supplies. Therefore, this can somewhat increase printing costs in the long run.

In a nutshell, dye-sublimation printers have distinguishing factors that set them apart from their counterparts, offering a host of remarkable benefits with vibrant, long-lasting prints being a significant one. Nonetheless, it's important to keep in mind the higher costs associated with consumables when considering this option.

Where Are Dye-Sublimation Printers Commonly Used?

Dye-sublimation printers are not limited to paper printing alone - they have gained considerable traction across numerous industries for their unique ability to create high-quality, full-color printouts. Their application ranges from an individual’s creative need to a necessity for bigger businesses. Here are the areas where the dye-sublimation printers are predominantly put to use:

1. Photographic Studios: Given the capacity of these printers to generate images with remarkable clarity and detail, many photo labs prefer them for producing superior quality photographic prints. They effectively capture delicate details and rich hues, thereby enhancing the overall output.

2. Promotional Material Production: Need to make personalized, vibrant printouts for promotional use? Dye-sublimation printers have got you covered. They are widely employed to create custom-designed t-shirts, appealing coffee mugs, eye-catching keychains, and other promotional items.

3. Fabric Printing: The fashion industry, sports apparel manufacturers, and home décor businesses often turn to dye-sublimation printers. The prints resulting from these printers are permanent, highly vibrant, and resistant to fading, thus making them suitable for fabric printing.

Also, surprising applications have been found in architectural and interior design for creating custom patterned textiles, transfers for furniture finishes, and even large-scale murals or reproductions of artwork.

Considering their varied usage, dye-sublimation printers are a testament to how print technology has evolved to serve diverse industries, thus expanding the horizon of possibilities in the world of printing.

What to Consider When Buying a Dye-Sublimation Printer?

Venturing into the world of dye-sublimation printing involves making a critical decision: choosing the right dye-sublimation printer. Understanding the range of considerations involved in this process can guide you towards a well-informed purchase decision.

Here are specific parameters you should factor in:

1. Printing Requirements: Your printer selection heavily depends on your specific printing needs. If your objective is to fulfil high-volume orders, for example, you'll need a printer that can handle this workload efficiently.

2. Resolution: The clarity and detail of your printouts hinge on the printer resolution. High-resolution printers can produce finely detailed images. However, they may come at a higher cost.

3. Printing Speed: If you run a business with high-volume print demands, look for a printer with a high printing speed. Time is crucial, and a fast printer can significantly streamline your printing operations.

4. Cost: Don't only consider the upfront cost of the printer. Take into account running costs too, such as the price of ink cartridges, print medium, and other parts over time.

5. Brand Reputation: Look for reliable brands known for quality and durability. Check customer reviews and ratings to get a real-life perspective on how the printer performs.

Remember, the best dye-sublimation printer for you is the one that satisfies your specific printing needs and fits within your budget. So, weigh your options carefully, and make a decision that ensures successful, seamless, and cost-effective printing operations.

Conclusion

While the world of dye-sublimation printers might sound complex, understanding their distinctiveness and functionality can help you make an informed decision when considering a printer purchase or identifying suitable printing techniques for your needs. Remember, the key to maximizing their benefits lies in aligning your printing requirements with the right features and capabilities.

Related FAQs about what is dye sublimation printers

What are the advantages and disadvantages of dye-sublimation printers?

Dye-sublimation printers have many advantages, such as producing high-quality, durable prints with vibrant colors and smooth gradations. They are also versatile, used in various industries from fashion to promotion. However, they also come with disadvantages like higher operating costs due to the need for specialized inks and print medium, and they may not be suitable for certain types of material.

How do I maintain a dye-sublimation printer?

Maintaining a dye-sublimation printer involves regular cleaning to avoid dust accumulation, checking and replacing the dye ribbon and paper when needed, and ensuring the printer heads are free of any residues. Always refer to the manufacturer's guidelines for more specific maintenance instructions.

Is a dye-sublimation printer a worthy investment for personal use?

Investing in a dye-sublimation printer for personal use depends on your specific printing needs. If you frequently print photographs, personalized gifts, or custom apparel, it can be a worthy investment due to the high-quality, vibrant prints. However, consider the initial and ongoing costs before purchase.