Versatile Uv Printing: Understanding What Surfaces Uv Printers Can Work With

Introduction

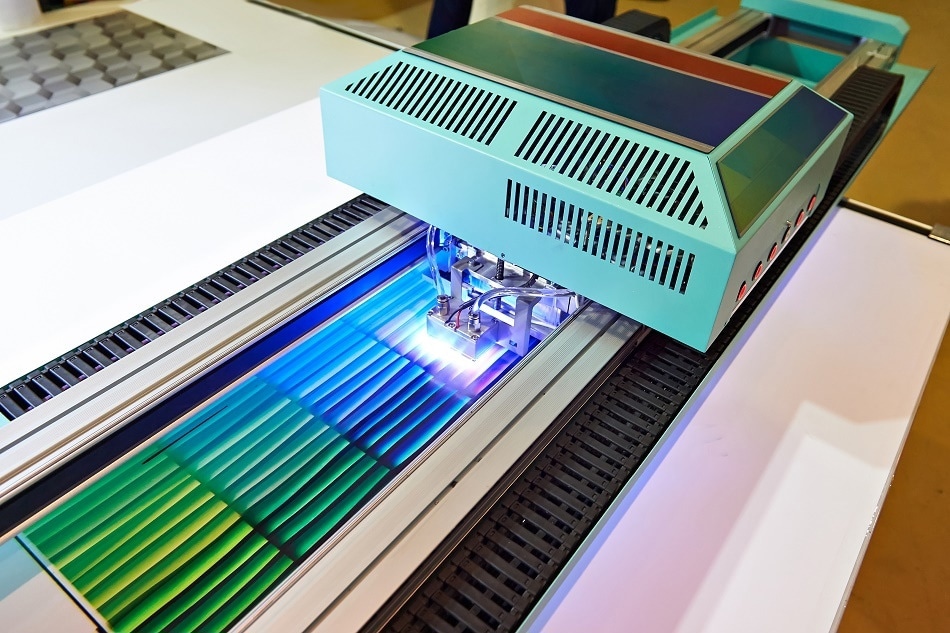

Printing technology has advanced rapidly in the past few decades, and one significant innovation is Ultraviolet (UV) printing. UV printing has revolutionized the printing industry, providing astounding graphics and images on a remarkable range of surfaces. With UV printers, what you can print on is limited only by your imagination. This versatile printing method is fast becoming an industry standard due to its efficiency and environmental benefits. In this article, we will explore what surfaces UV printers can work with, how UV printing impacts different materials, the ongoing innovations in UV printer use, and its future direction.

What is UV Printing?

UV Printing, a pivotal technological breakthrough in the printing industry, employs Ultraviolet light technology to solidify the ink instantaneously. This contemporary printing procedure offers high-quality print results with attention-grabbing color precision and prevents smudging or ink spreading. The following key components characterize UV printing:

- Instant Curing Process: Unlike conventional printing methods that demand time for drying, UV printing uses UV light to dry or 'cure' the prints instantly, reducing production time significantly.

- Adaptable to Many Surfaces: UV printing has an edge due to the vast range of materials it can print on. It's possible to use UV printers on surfaces such as paper, plastic, glass, metal, and even textiles, which is generally not possible with traditional printing methods.

- Vibrant Colours: The ink from UV printers does not absorb into the material, resulting in bright print results with exceptional color depth.

- Environmentally Friendly: UV printers consume less energy, and as the ink dries instantly, it doesn't permeate the material or evaporate into the atmosphere. Hence, this printing method is more eco-friendly.

- Long-Lasting Print Results: As the dried ink forms a hard layer on top of the printed material, UV prints are more resistant to weather, wear, and water, resulting in a long-lasting print that can endure harsh conditions.

To sum up, the benefits of UV printing and its efficiency make it a fast-growing technology in the printing industry, constantly advancing and expanding horizons.

What Surfaces Can UV Printers Work With?

UV printers stand out for their adaptability, capable of taking on multiple types of surfaces, going beyond the standard ones such as paper and cardstock. This wide range of printing possibilities stems from their highly advanced and unique printing techniques.

Exploring UV Printer's Versatility over Textile Printing

UV Printers are just as effective on textiles as they are on any other medium. Assimilating an array of fabrics - cotton, silk, polyester, etc., UV Printers infuse high-quality prints that thoroughly resist smudges or fading over time, transform textiles into lasting pieces of arts.

• Bright and Vivid Prints: UV printers can produce vibrant, sharp prints on all fabrics.

• High Durability: The prints are highly durable, resilient to washing and everyday wear and tear.

• Instant Drying: Given UV printers' ability to dry prints instantly, there'll be no blotching or spreading ink.

UV Printing on Glass and Metal: A Breakthrough in Printing Innovation

UV Printing's capabilities also extend to rigid surfaces such as glass and metal. This outcome results from the UV curing process, which solidifies the printer's bond with the material in any form or texture, thereby creating clear, high-resolution, and long-lasting prints.

• Durability: UV printing on glass or metal offers durable and long-lasting prints. It's perfect for creating permanent signage, decorative items, and more.

• Vivid Images: The print quality is excellent, making for bright, high-definition images.

• Effectiveness: UV printers, unlike traditional printers, can efficiently work on non-porous surfaces like glass and metal.

UV printing's versatility presents unique opportunities for creative applications, from developing attractive marketing materials to designing captivating home décor pieces. With its range of usable surfaces continuing to expand, UV printing is carving its niche as a staple in the printing industry.

How Does UV Printing Impact Different Materials?

The way UV printing influences different materials can significantly affect the final outcome. The characteristics of the materials - their texture, absorption rate, or reflective properties - all play a vital role in the overall appeal of the printed item. In this section, let's embark on understanding these effects:

Impact on Smooth Surfaces like Glass and Plastic

When UV printing is applied on smooth surfaces, specifically glass and plastics, the result is impressive:

- High Gloss Finish: The UV light reacts to the ink on these materials, creating a high-gloss finish that is both eye-catching and professionally appealing.

- High Image Clarity: UV printing on these materials results in high-definition images with clear lines and detailed graphics. The ink does not bleed into the material, producing a clean, sharp image right on the surface.

Impact on Rough, Textured Surfaces like Wood and Fabric

Working with textured surfaces such as woods and fabrics can result in an entirely different finish, though no less impressive:

- Textured Finish: As the UV light cures the ink on the textured surface, it preserves the natural feel of the material. This results in a beautiful, textured finish that adds an extra dimension to the print.

- Color Absorption: Fabric material absorbs the UV ink well, creating vibrant and long-lasting colors.

- Longevity: On wooden surfaces, UV printing has been found to be resilient to environmental factors like sunlight and water, extending the lifespan of the printed material.

Impact on Paper and Cardstock

- Quick Completion: When using UV printing on paper and cardstock, the immediate curing process allows for faster project completion times.

- Smooth Finish: Since UV ink doesn't soak into the paper, but rather sits on top, it creates a smooth, professional finish without bleed-through or smudging.

Examining these impacts helps in understanding why UV printing technology is so versatile. Whether you need to print high-quality graphics on smooth surfaces like glass or want a textured print on wood or fabric, UV printing technology can deliver superior results.

What Are Innovations are There in UV Printer Use?

The dynamism of UV printing does not stop at its ability to work on various surfaces. This technological marvel pushes boundaries to deliver unanticipated innovations that redefine the conventional ways of printing. It's remarkable how UV printer use has innovatively evolved to yield better output. Some eye-catching advancements include:

Use of White Ink:

Traditionally, printing on darker materials meant compromising on color vibrancy. However, the introduction of white ink in the UV printers gave rise to better color reproduction and contrast. It acts as a base for other colors, thereby enhancing the overall print vibrancy, which is especially noticeable on transparent and dark surfaces.

Embossed Printing:

Embossed printing refers to creating 3D-like textures on paper surfaces. This wasn't plausible until UV printers came into play. They can lay multiple layers of ink on the surface, creating an embossed effect, thus giving the print a tactile element that both looks and feels interesting.

Uneven and Curved Surfaces:

One of the most notable advancements in UV printing is its ability to print not only on flat surfaces but also on objects with uneven or curved contours. This is a significant leap from traditional printing methods and allows for creating a unique user experience with a broad spectrum of applications.

Digital Varnish:

The use of digital varnish is another innovation in UV printer use. It’s used to get a glossy finish, which had been a challenge with other print technologies. This gloss gives the print extra protection against factors such as scratching and exposure to water or moisture.

These game-changing innovations are undeniably shaping the future of the printing industry. Constant developments in UV printer technology promise even more exciting innovations to come, broadening its application. Today, UV printing is increasingly becoming the preferred choice across several sectors – from commercial to industrial and even domestic applications. The versatility and quality it offers are unparalleled, making it an asset in the ever-evolving world of printing.

The Future Direction of UV Printers

As the printing industry continues to evolve, UV printing technology isn't being left behind. Here are some exciting future trends:

1. Expanded Material Usage: UV printers will be engineered to handle more diverse materials, including various textiles and ceramics, giving designers more creative possibilities.

2. Greater Energy Efficiency: The shift towards UV LED printers is foreseen to continue. UV LED printers are renowned for their energy-efficiency and durability, offering a long lifespan and the ability to accommodate a wider range of materials compared to traditional UV printers.

3. Enhanced Printing Capabilities: The future might unveil UV printers with the capacity to print white ink, enhancing color vibrancy and creating deeper contrasts. Emphasis will also be on the creation of embossed prints to add texture and depth to the print surface for an intricate 3D effect.

4. Technological Advancements: Automation and AI advancements are predicted to play a crucial role in future UV printers, making them more user-friendly and providing better control over the printing process.

It's clear the future of UV printers is bright, boasting of transformation and increased capabilities.

Conclusion

UV printer technology is rapidly evolving, with new applications and advancements emerging regularly. Some of the innovations include the use of white ink for improved color contrast and reproduction, embossed printing for 3D-like textures, and the ability to print on objects with uneven or curved surfaces with digital varnish for a glossy finish.

The introduction of UV LED printers has also revolutionized the industry. These printers are more energy-efficient, have longer lifespans and can work with a broader range of materials than traditional UV printers.

Related FAQs about what can uv printers print on

What types of materials are best suited for UV printing?

UV printing is incredibly versatile. It works well with a plethora of materials, including paper, plastic, glass, metal, and textiles. This makes it a preferred choice for various applications, from commercial signage to artistic creations.

How Environmentally Friendly is UV Printing?

UV printing is considered environmentally friendly. The instant curing of the ink reduces energy consumption, and because the ink does not absorb into the material or evaporate into the air, there is less waste and pollution.

What are the main benefits of using UV printers over standard printers?

UV printers offer several advantages over standard printers. They provide high-quality, vibrant, smudge-free prints and can print on a wide range of surfaces. The printing process is faster due to instant ink curing, and the end result is durable and long-lasting.